How does the selection and ratio of reaction gases affect the composition and performance of vacuum coating?

In chemical vapor deposition (CVD) vacuum coating, the selection and ratio of reaction gases are like a pair of invisible but powerful hands, playing a decisive role in the composition and properties of the coating.

What are the advantages of high-energy pulse PVD technology compared to traditional PVD?

Higher density:High energy pulse PVD can generate high-density plasma during the deposition process,giving deposited particles higher energy and forming a denser film layer on the substrate.For example,in the preparation of hard coatings,

What film layers can be prepared by high-energy pulse PVD technology?

Such as titanium nitride(TiN)film layer.TiN has high hardness,good wear resistance,and chemical stability.TiN film layer prepared by high-energy pulse PVD technology is widely used in the field of tool coating

What is the basic physical principle of high-energy pulse PVD?

PVD is a technology that deposits a coating on the surface of a workpiece by evaporating a target material at high temperatures.High energy pulse PVD is an improved form of PVD technology,and its basic physical principles are as follows:

What is the process flow of vacuum coating

Vacuum coating is a technology that forms a thin film on the surface of a material,and the main process includes the following key steps.

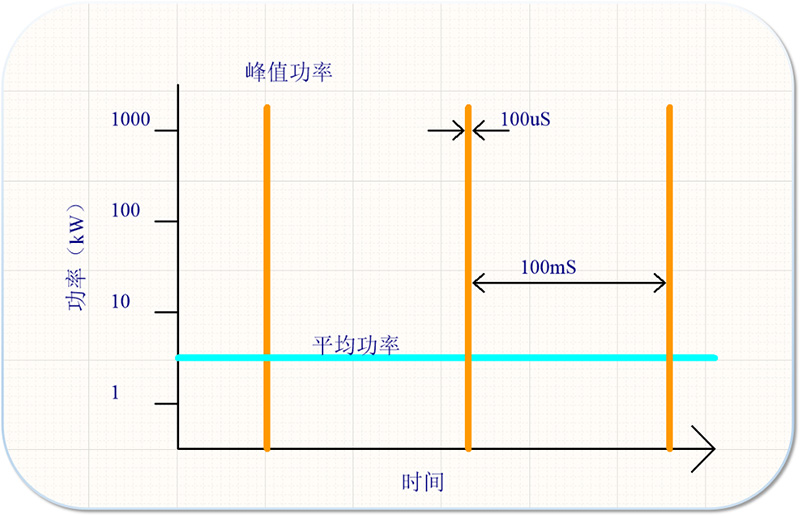

HiPIMS Magnetron Sputtering: A New Trend in Material Preparation

In the field of material preparation,HiPIMS(High Power Pulse Magnetron Sputtering)magnetron sputtering is gradually emerging as a new development trend.

Can HIPIMS power supply be used as a bias power supply

HIPIMS(High Power Pulse Magnetron Sputtering)power supply can be used as a bias power supply under certain conditions,but there are also some limitations.

How is the measurement and control of film thickness achieved in vacuum coating technology?

In vacuum coating technology,measuring and controlling the thickness of the film is a key step in ensuring the quality of the coating.

1、Measurement method for film thickness

0769-81001639

0769-81001639